Fermentation might sound odd in the context of coffee. We usually encounter it with alcohol, most notably wine and beer. The purpose is to break down complex sugars into simple sugars and acids. Whereas the process for alcoholic beverages ends when a large amount of the sugars are converted to ethanol and CO2, for coffee, it is before any alcohol is produced. Fermentation is an inherent part of the coffee industry. When the fruit is first harvested, the crown, where the branch connects to the cherry, becomes a playground for microbes. They begin entering the fruit, where our fermentation process begins. Coffee harvesting and transport is a tedious job, and over a few days before processing begins, the batch of coffee has slowly and unevenly begun fermentation. This means fermentation has begun before any processing of the coffee. The primary aim of fermentation is to break down the mucilage and dry the cherry.

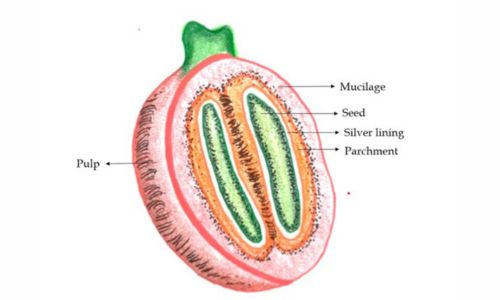

To understand the process of fermentation, you must first understand the structure of a coffee cherry. The fruit is comprised of layers, and any kind of processing of coffee involves removing those to expose the bean or seed inside. The outermost, pericarp, comprises the crust (exocarp), mucilage (mesocarp), a pectin layer, and parchment (endocarp). There is then a layer of silver skin, followed by two beans in the middle. The mucilage is largely comprised of polysaccharides and large chains of complex sugars.

There are two broad types of coffee processing. They are dry (or natural) and wet (or washed) coffees. The dry process means that after harvest, the cherries are washed and laid out to dry in beds. After a period of simultaneous drying and fermentation by either added or native microbes, the coffee is peeled to get rid of the pericarp and expose the bean underneath. The drying means the pectin present in the mucilage slowly ferments and absorbs through the parchment. Dry-processed coffee is known for its winey and acidic taste profile. The green bean (which is a post-process and pre-roast coffee bean) is then stored for roasting.

In the wet process, the cherries are first washed, and the fruit is mechanically pulped to remove the exocarp. At this point, the beans are still covered with mucilage. The beans are then placed in a vat of water and fermented. There is very little fruit remaining on the bean, so the fermentation is much shorter than in the case of the dry process. The concentration of acids and simple sugars produced is also much smaller, which, being submerged in water, does not absorb into the parchment, and is instead washed away. This results in a much sweeter and more balanced coffee, largely free of the funkier flavors of the dry process. The beans are then washed and dried, ready for storage as green beans and subsequent roasting.

The above processes are very broad; in actuality, there are hundreds of kinds of processes out there right now, ranging from simpler and more traditional ones like semidry or honey-processed to very outlandish-sounding ones like carbonic maceration and thermoshock. While these may all sound like pretentious jargon (and some might just be), they allow producers to add to and improve their coffees, give you more flavor, and provide more unique experiences. As producers become more specialized in processing, they stop doing what has always been expected of them, which is to have minimum involvement and not interfere with the natural taste of coffee. Today, more than 700 volatile and non-volatile compounds that contribute to coffee flavor after fermentation have been identified. That is a staggering range and is possible due to the experiments of producers and their growing familiarity with microbes.

The coffee’s varietal, origin, and level of roasting determine the constitution and quantity of the flavor resulting from these compounds. During coffee fermentation, microorganisms produce diverse metabolites. Microbial activity and the extent of fermentation determine the concentrations of free sugars and amino acids that continue to surround the bean (and subsequently contribute to the production of Maillard compounds and volatiles during the roasting process). They contribute to the breakdown of cellulose and pectin substances that exist in the skin, pulp, and mucilage of coffee cherries and contribute to the production of lactic, butyric, acetic, and other higher carboxylic acids, as well as sugar acids. The three most important enzymes produced by microbes for degrading pectin during coffee fermentation are pectin lyase (for pectin degradation to unsaturated sugar acids), polygalacturonase (to convert pectin into pectic acid), and pectin methyl esterase (to deesterify pectin to form methanol and pectic acid).

As for the microbes themselves, they range from yeasts to bacteria and even fungi. Regardless of whether the producer adds microbes to initiate fermentation, coffee cherries are grown outdoors, where a myriad of microbes settle on the surface. With cuts and bruises on the skin, they enter the fruit and begin enzyme activity. Even without big points of entry, smaller microbes like bacteria can enter the cherry through the skin. After harvest, this activity only increases as the crown is exposed.

All microorganisms do not have the same effect on the cherry, just as microbes have very different activities depending on the atmosphere. For example, the yeast Saccharomyces cerevisiae, which is widely used industrially for different purposes and found naturally during coffee processing, is known to produce mainly ethanol under anaerobic conditions, but under semi-anaerobic and aerobic conditions, it is capable of producing compounds of sugar acids like succinic and lactic acids. This shows the necessity of maintaining as sterile an environment as possible after washing and monitoring the fermentation closely. Climate, time, temperature, altitude, the kind of native microbes, and the desired outcome all must be kept in mind. Increasing the complexity of processing methods only makes this more crucial.

Coffee is so much more than a dark, bitter liquid to be gulped down; it can be rich, vibrant, sweet, and delicious. Historically, it has had a rather unfair reputation due to growing demands and pressure on farmers. Empowering and educating farmers and producers is essential for its survival and sustainability, and looking for what coffees are out there is a crucial first step to recognizing that there is a whole world of complexity you don’t want to miss out on.

References:

- https://www.luxia.coffee/

- Haile, W. H. Kang, Journal of Food Quality 2019, 2019, 1–6.

- Schwan, C. Silva, L. Batista, in Handbook of Plant-Based Fermented Food and Beverage Technology, Second Edition, CRC Press, 2012, pp. 677–690.

- Huch, C. M. A. P. Franz, in Advances in Fermented Foods and Beverages, Elsevier, 2015, pp. 501–513.

- Elhalis, J. Cox, D. Frank, J. Zhao, International Journal of Food Microbiology 2020, 333, 108796.

. . .

Writer

Ved Joglekar

Editor

Dhanashri Satav

Illustrator

Shruti Morjaria